Male Adapter RAM-UO

Male Adapter RAM-UO

The Male Adapter (RAM-UO) serves as a crucial component in fluid handling systems, facilitating a secure connection between male-threaded and female-threaded components. It ensures efficient fluid or gas transfer while maintaining system integrity and reliability.

Applications

➢ Plumbing Systems: Utilized in residential, commercial, and industrial plumbing systems for connecting pipes, valves, and fixtures.➢ Fluid Handling Systems: Integral component in fluid handling applications such as hydraulic systems, process piping and pneumatic systems.

➢ HVAC Systems: Deployed in heating, ventilation, and air conditioning (HVAC) systems for connecting pipes and components.

➢ Industrial Equipment: Essential in various industrial equipment and machinery requiring fluid or gas transfer.

➢ Automotive Industry: Employed in automotive systems for connecting fluid lines, including fuel lines, coolant lines, and hydraulic systems.

➢ Marine Applications: Utilized in marine systems for fluid transfer within vessels and offshore installations.

Connects fractional port to SAE straight thread boss

Key Features

➢ Male Threaded End: Equipped with external threads on one end, specifically designed to mate with a female-threaded component such as a pipe, valve, or fitting.➢ Adapter Functionality: Acts as an intermediary interface between components with different thread types or sizes, offering versatility in system design and configuration.

➢ Robust Construction: Constructed from high-quality materials such as stainless steel, brass, or PVC, ensuring durability, corrosion resistance, and longevity in various operating environments.

➢ Precision Engineering: Engineered with precision tolerances to ensure a tight and reliable fit, minimizing the risk of leaks or system failures.

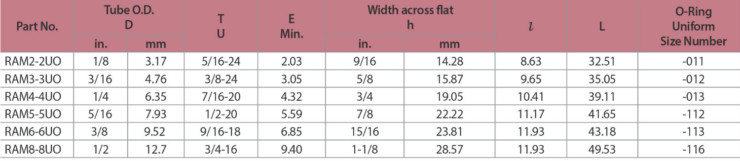

➢ Variety of Sizes: Available in various sizes and thread configurations to accommodate diverse system requirements and specifications.

➢ Sealing Mechanism: Incorporates effective sealing mechanisms such as O-rings or gaskets to establish a leak-tight connection, maintaining system integrity.

➢ Easy Installation: Designed for straightforward installation, reducing installation time and labour costs during system setup or maintenance procedures.

Obtaining Specifics

➢ Manufacturer's Documentation: Refer to the manufacturer's product specifications, datasheets, and installation guides for detailed information on sizing, materials, pressure ratings, and installation procedures.➢ Supplier Catalogs: Explore supplier catalogues specializing in fluid system components for comprehensive details on Male Adapter options and compatibility with specific systems.

➢ Consultation: Seek guidance from industry experts, engineers, or suppliers to ensure the selection of the appropriate Male Adapter based on specific system requirements and environmental considerations.

Benefits

➢ Reliable Connection: Provides a secure and leak-free connection between male-threaded and female-threaded components, ensuring dependable fluid transfer.➢ Versatility: Compatible with various fluid types and system configurations, offering flexibility in system design and implementation.

➢ Durability: Constructed from robust materials, ensuring long-term performance and resistance to corrosion and wear.

➢ Ease of Installation: Designed for straightforward installation, reducing downtime and labour costs during system setup or maintenance activities.

➢ Minimal Maintenance: Minimizes the risk of leaks and system failures, reducing maintenance requirements and enhancing system reliability.

➢ Cost-Effectiveness: Offers cost-effective solutions for fluid system connections, contributing to overall system efficiency and performance.

↪ The Male Adapter (RAM-UO) is an essential component in fluid handling systems, providing a reliable and efficient connection between male-threaded and female-threaded components. By selecting the appropriate Male Adapter and following recommended installation practices, system integrity and performance can be maintained, ensuring the seamless operation of fluid transfer applications.